Saturday, 2 June 2012

Monday, 28 May 2012

Almost done

The legs after being powdercoated in textured black. Cheap and good! Professionally powdercoated by, you guessed it, Mr. Powdercoat.

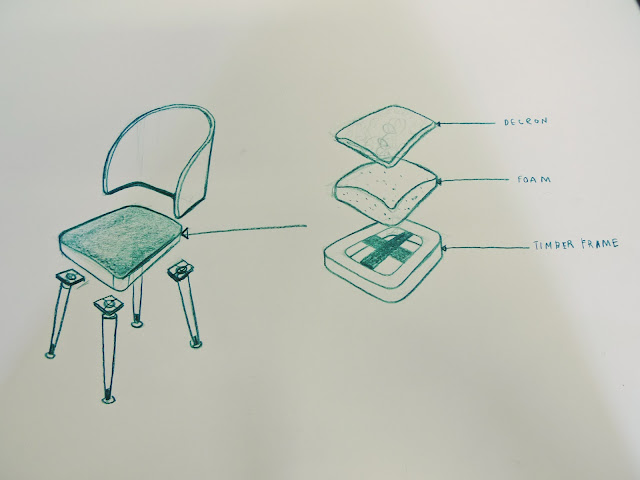

The seat was given a new lease of life. New fabric, new dunlop foam, new decron, new webbing! Professionally done by Rohan Jago from Nucleus Designs.

Almost done! Except for attaching the two parts together. Pictures above show the seat resting on the base temporarily.

Thursday, 24 May 2012

All about metal legs

To attach the legs to the seat, an additional component was needed. This piece will hold the legs together at the top and be fastened to the seat's timber frame with some screws.

The timber frame looked like this from the bottom >>>

The timber frame looked like this from the bottom. The piece would need to fit within this frame and be hidden from view.

The initial design looked like this. However, there were concerns that there might be too much excess weight. So I redesigned it. To do so, I CADed up the timber frame and printed it out one-to one to use as a template.

I then positioned scrap metal bars such that they fit within the frame, and at the same time will intersect with the points of contact with the steel rods.

And I ended up with the above configuration. This is sheer function without form. It was not designed to look pretty (since it's going to be hidden anyway). But by coincidence, I happen to quite like how it sort of mimicks the polygonal shapes of the legs.

Now we just had to weld them all together. Had some help from Andrew this time.

I then cleaned up the blobs from the weld with an angle grinder. And to finish it off, some sanding with the file.

And done!

Welding it together

The next step was to weld the loose rods together. A jig was needed to hold the rods in its exact place so the welding can take place accurately and quickly. The overall form of the legs is rather complex, different angles, different heights, intersecting components. Hence a detailed jig with accurate information is needed so that the perfect piece can come together. About a day later, I came up with this >>>

Putting the rods in their positions >>>

And finally, welding it!! >>>

Fun times.

Bending Rods

The next stage was to get the steel rods bent. To do so, a one-to-one flat pattern was needed. The components were CADed up and printed on an A0 paper to be used as a template.

8mm steel rods marked and trimmed. It was then heated with an oxy and bent by hand. The bent rods were frequently placed on the template to check if the angles were right. After about 2 days work, the 5 components were finally completed!

Sadly, no pictures were taken that day because bending the rods was a daunting process (my first time) and snapping pictures were the last thing on my mind. But it was an exhilarating experience. And seeing those linear rods take shape using heat and arm power was quite something.

Hole in the Back

The process of removing the back from the seat proved to be too rough for the delicate backrest. Some of the veneers were peeling away. So before cutting a hole in the centre, I had to glue and clamp it back together.

To cut the hole, I drew up several templates to see which sizes would work best aesthetically and structurally. I wanted the form to be quite elegant and visually light. But I had to take into account the stress-points, and the pressure of a person sitting down and leaning back.

Once the shape was locked down, I used charcoal to mark it out directly on the back and was ready to cut it out! After a few practice runs in the definitely-will-not-use-areas, I used a multitool with a blade attachment to cut it out. Cleaned up the edges first with a chisel, and then some sanding with a dremel.

Exposing the Back

Spent a friday trying to remove the backrest from the seat. I had to pull out tons of staples, and after stripping away the fabric and foam, the bent ply was finally exposed.

The surface was really clean. Which was a nice surprise as I had expected to see the foam glued onto the ply. What was horrible though, were the marks left behind by the staples.

The plan originally was to leave the ply as it is, so that the material and construction can be showcased. But after seeing all those unsightly marks, I had to re-evaluate that decision. At this point, I was considering to upholster the back together with the seat. (Initially, I only thought of re-upholstering the seat). It was not only for practical reasons of covering those marks, but I also grew to like the idea of having only two elements (fabric and steel), instead of the initial three elements (timber, fabric and steel).

Tuesday, 3 April 2012

Chosen concepts

-Elaborate backrest is made visually lighter.

-Timber legs are kept simple to emphasis the backrest

-Exploring to have the seat facetted

-Focus on lines

-Legs and frame to be made with rods and tubes

-Exploring to have backrest and seat in a clear plastic (perspex)

-armrest incorporated into chair

Tuesday, 27 March 2012

Ideation

Some concept development sketches. Here I was trying to create the illusion of an elaborate backrest while still keeping it visually light. I also played with the possibility of combining the backrest and front legs into one fluid piece. While exploring different forms, I found drawing a simple profile of the side gave me much inspiration for three-dimensional forms.

Examining the backrest

I first thought the upholstery was glued onto the backrest. The fabric was stretched tautly without any creases and it was very neat. However after ripping the staples away, the fabric fell apart and revealed the plywood underneath. It was not glued on like what I expected. My first thoughts were, the craftsman did a very neat job but went crazy with the staple gun, because it took ages to remove just a section of it. The clean plywood also meant that reusing this part would be possible. This plywood backrest was connected to the seat with several nails at the bottom. Now if only that would be as easy to rip out as the staples.

I want the new chair to...

- Remain a dresser chair

- Retain some of its opulence, but without the kitsch

- Be quite delicate and with feminine qualities

- Easily incorporate with any dresser- super modern or very

traditional

- More 'beautiful' than utilitarian

- Have a good proportion/balance of big backrest to short legs

Tuesday, 20 March 2012

My Chair: Photo essay & written statement

Judging from its appearance, this chair seems like a 1970s dresser chair.

Its low seating, dainty size and feminine form are features that suggest it

serves that particular use. Its oversized backrest can serve the function of a makeshift

rack for clothes and other wardrobe peripherals to be temporarily hung on,

another reason why it could be a dresser chair.

The style of the chair is a blend of traditional and contemporary,

an attribute of the 1970s postmodern movement. The form of the chair is simple,

incorporating clean lines and organic curves, and its legs are tapered thin

towards the end without any fussiness. All of which follow the principles of

modern design. Yet, there is an injection of ornamentation and old world charm

with its choice of fabric. The upholstery of the chair is dramatic and made

elaborate in floral patterns, evoking a Victorian vibe. This however is again

toned down in a muted color palette of ivory. This balance of old and new,

utilitarian and decoration, gives the chair its 70s postmodern characteristics.

The construction of the chair seems to be done by conventional

manufacturing methods using conventional materials. The legs are mostly made

out of timber and the tips that would come into contact with the floor are

attached with circular metal fittings to give the chair more balance. It is

then screwed on to a metal fitting that is attached to the pinewood frame of

the seat.

When disassembled, the seat consists of 4 main parts- the pinewood

frame, foam, decron and fabric for upholstery. The backrest is a piece of curve

plywood manufactured using the bent lamination technique, in which wood veneers

are stacked, glued and pressed with molds. When completely dried, the backrest

is then covered with decron on one side and upholstered with fabric.

Subscribe to:

Comments (Atom)